Images

Name of vessel

Ailsa Craig I

Previous Name

Ruby III, Orpheus Asia

Registry

Panama

IMO No. / Call Sign

8907319 / 3EMW8

Builders

IHI Kure, Japan

Year of Delivery

30 Dec 1990, 2011 Converted to FSO at CSSC Dockyard, Guangzhou,China

Hull No.

2995

Type

Floating Storage and Offloading Unit, Single Hull

Classification / Notation

Russian Maritime Register of Shipping / KM * FSO

Deadweight

318,000 MT

Length Over All (LOA)

343.40 m

Length Between Particulars (LBP)

322.20 m

Breadth (Moulded)

58.00 m

Depth (Moulded)

28.55 m

Draft (Summer)

22.02 m on full deadweight

Lightship

36,672 MT

GRT / NRT

150,704 T / 150,204T

Crude Oil Washing System (C.O.W.)

All cargo tanks are fully equipped with COW machines

Inert Gas System

Boiler flue-gas system servicing all cargo tanks

Fiscal Metering System

DANIELS designed with 3x16" streams with Smith Metering PD meters 12.000 bbl/Hr each stream. Newly installed in 2012 Emerson Sentinel 600 flow computers, computerized operating monitoring system at CCR, Prover loop with bi-directional sphere

Cargo Control Room (CCR)

Integrated with tank radar system with central control console for cargo handling and inline loading software, ESD systems management, response and communications systems, CCTV coverage of import/export platforms, fiscal meter, tandem mooring arrangement, aft hawser tension monitoring system, ODM monitoring system

Cargo Pumps

3 steam turbines 4,500 cm3/Hr

Cranes

2 x 20T at 18m – Hydraulic

1 x 20T at 25m – Hydraulic + 2.5T man-riding at 27m

Propulsion Engine

1 x DU Sulzer 7RTA 84M / 27520 BHP at 65.5 RPM fully operational

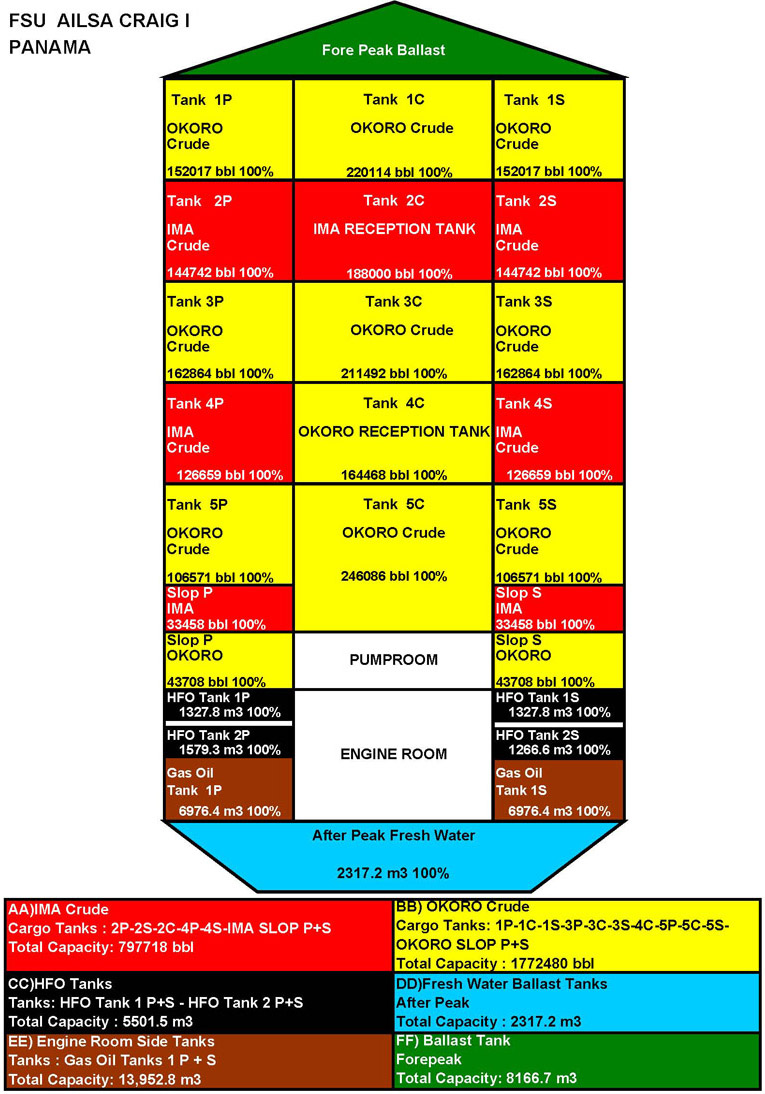

Cargo Capacity

Total Cargo Capacity: 2,570,201 bbl in two totally segregated grades.

1st Grade Capacity: 1,685,066 bbl + Slop Tanks 87,416 bbl

1 Reception Tank, 9 Storage Tanks + 2 Slop Tanks

2nd Grade Capacity: 730,803 bbl + Slop Tanks 66,916 bbl

1 Reception Tank, 4 Storage Tanks + 2 Slop Tanks

Gas Oil Storage Capacity : 14,264 cm3

F. W. Storage Capacity : 2,758 cm3

Mooring System

Permanent 14 points spread mooring system equipped with anti-piracy cobra protective plate

Export Mooring System

Tandem export tanker mooring arrangement serviced by a pair of self releasable chain stoppers with load cell and fully computerized readout, alarm and data logger system at CCR

Loading System

Fully equipped import platform amidships starboard side with 12" riser connection and E.S.D. system, deluge system, pig receiving system

Discharge System

Stern export platform with 16" hose connected to floating export line with E.S.D. system, deluge system and machinery shut down system

Helideck

Full Offshore standards as per CAP437 for S92 (12T) serviced by main and independent FOAM System, night landing lights, air band radio

Accommodation

Designed to accommodate totally 72 persons crew, visitors and customer suite

Fire Extinguishing System

Fully equipped with FWD and AFT independent FOAM & fire pumps Fixed FOAM fire extinguishing system for Engine and Pump rooms

Power Generator

4 x Daihatsu 6DLB 26 /1350 PS x 720 RPM diesel engines with alternator 900KW each unit

Back up Power Systems

1 x Cummins KTA 38 4G – 800KW at 1800 RPM

1 x Detroit Diesel Engine 6-71T / 190 KW at 1800 RPM

Boiler

1 x IHI – ADM 1007 Capacity 84,000 kg/Hr, Working pressure:16kg/cm2

Fresh Water Generators

1 x Sasakura-Atlas AFGU KM 40 capacity 40T/day

1 x Reverse Osmosis Unit 75T/day

Oily Water Separator

1 x TAIKO UST-20N 2T/Hr

Inmarsat C / Fleet 77

JRC – JUE-75A

Furuno – FELCOM 70

Radar

1 x Tokimec BR-3440CA-S314 S-Band

1 x Tokimec BR-3440CA-X27 X-Band

ARPA Radar

2 x Tokimec A-823 (19)

CCTV Monitoring System

Bridge control and monitoring system of 18 sectors covering surrounding the FSO